Supply Planning#

The Supply Planning module is designed to help supply chain managers and planners maintain optimal stock levels, prevent shortages, and manage purchase orders efficiently. It combines AI-powered recommendations with manual flexibility, ensuring that businesses can make proactive and informed decisions.

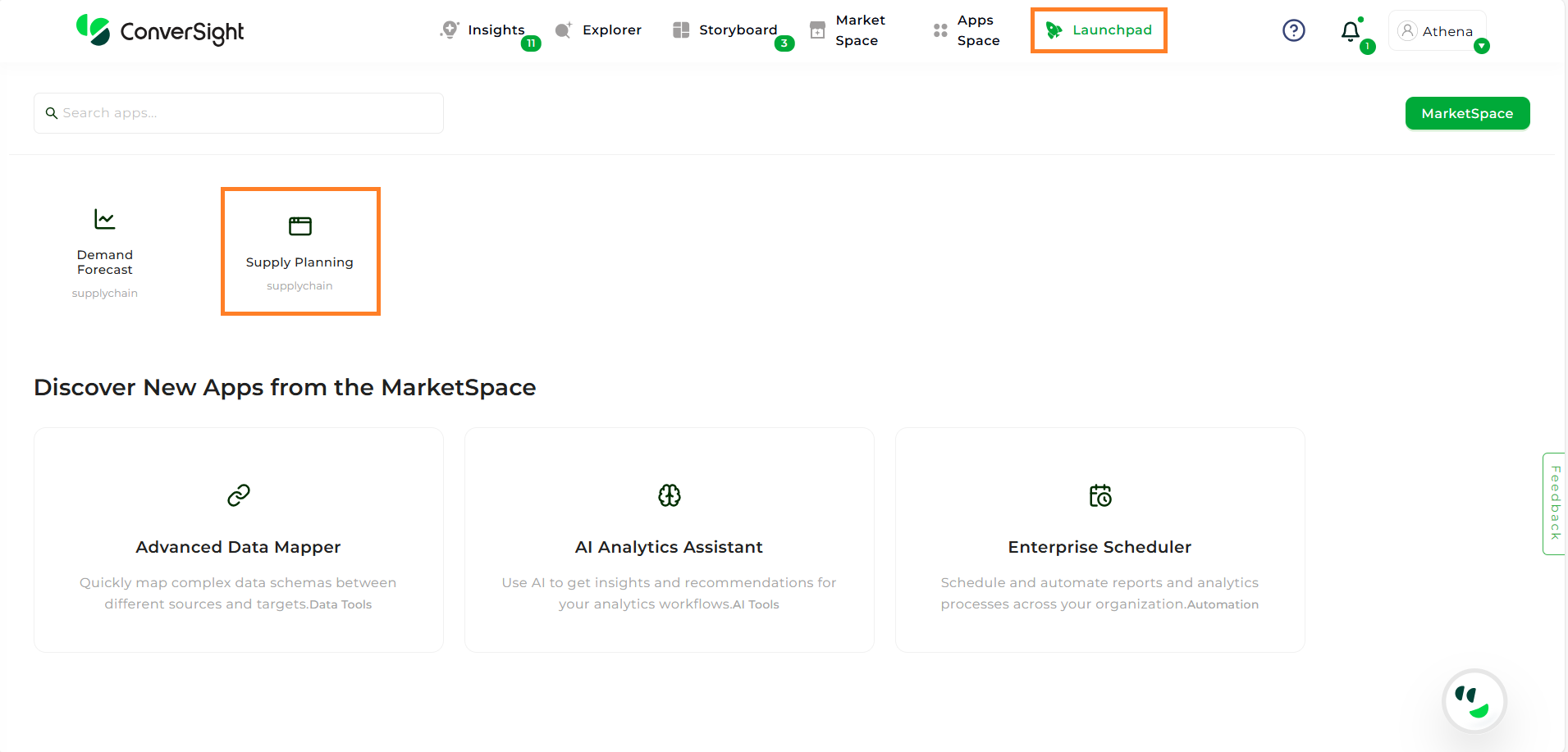

Accessing the Supply Planning App#

From the Launchpad, users can click on Supply Planning. The Supply Planning Dashboard will open, displaying a list of supply configurations.

Access Supply Planning#

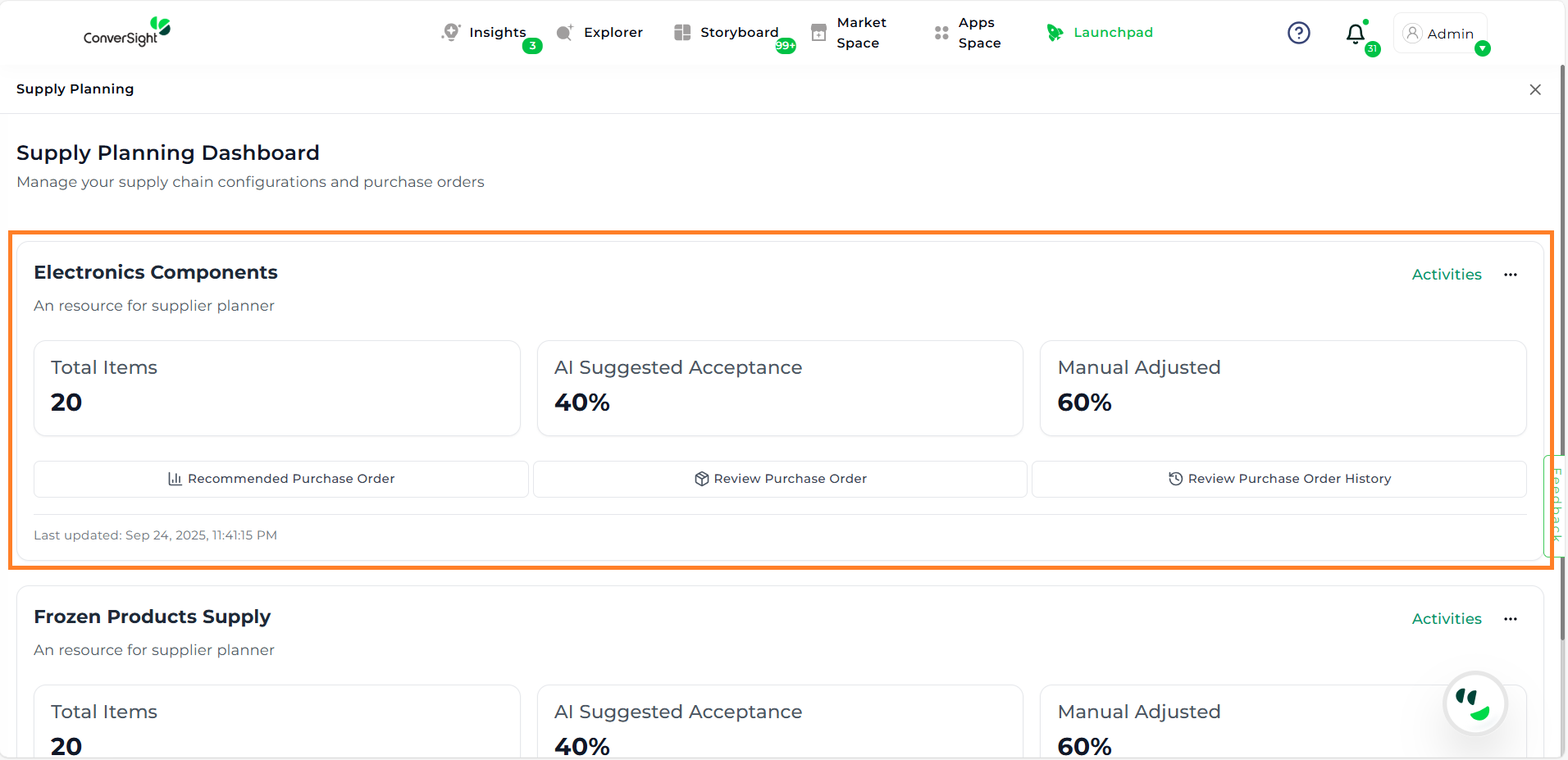

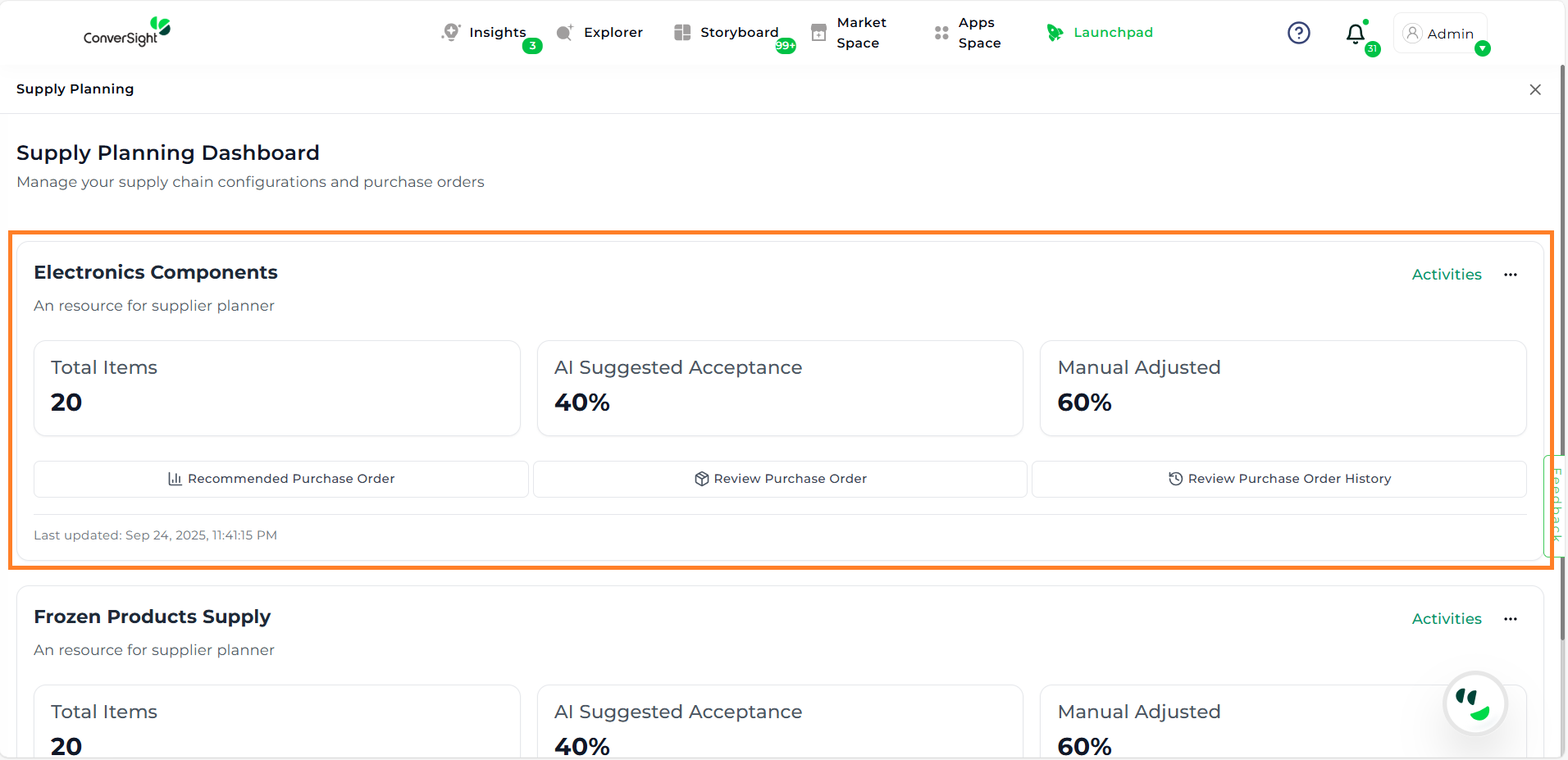

Supply Planning Dashboard#

The dashboard provides a high-level overview of all configurations. Each configuration card contains the following details:

Total Items – The total number of items included in the configuration.

Configuration Name & Description – A label and summary of what the configuration monitors.

AI Suggested Acceptance % – Percentage of AI-generated recommendations that were accepted.

Manually Adjusted % – Percentage of orders that were manually modified by users.

Supply Planning Dashboard#

NOTE

Each configuration card can be accessed by multiple users; however, the data saved for PO creation is shared across users, and no user-specific sessions are maintained.

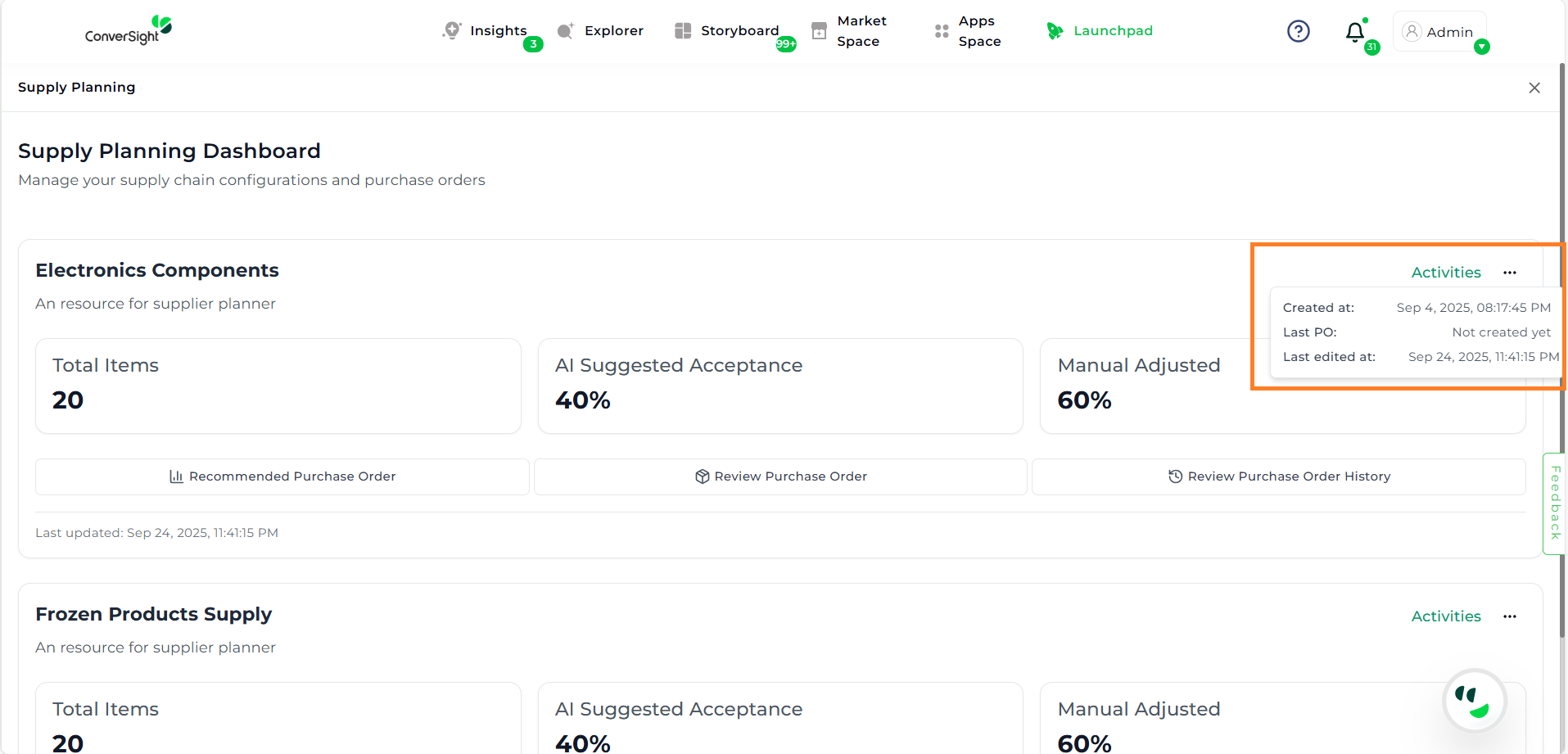

Activities Section#

The Activities Section provides key timeline details related to the configuration’s creation, updates, and Purchase Order (PO) activity. It helps users track when configurations were last modified or used to generate a PO.

Created At – The date when the configuration was originally created.

Last PO – The date when the most recent Purchase Order was generated from this configuration.

Last Edited At – The date and time when the configuration was last updated or modified.

Activities#

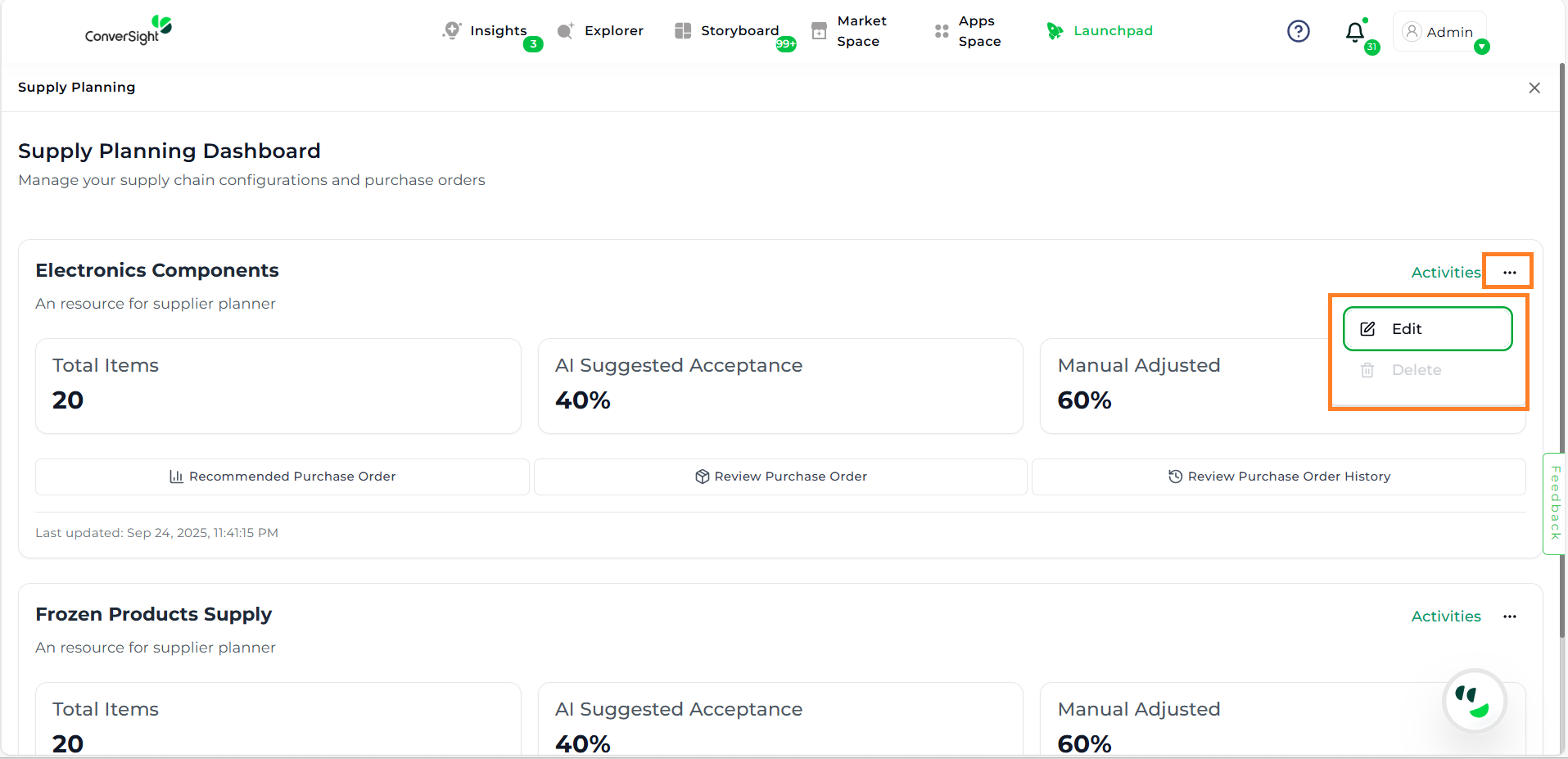

Editing a Configuration#

To make changes to an existing configuration:

Step 1: Locate the configuration you want to update.

Step 2: Click on the three dots menu in the top-right corner of the configuration card.

Step 3: Select Edit. This opens the Edit Screen, which has two tabs:

Recommended – Provides AI-driven supply and demand insights.

Review – Allows users to finalize selections and create Purchase Orders.

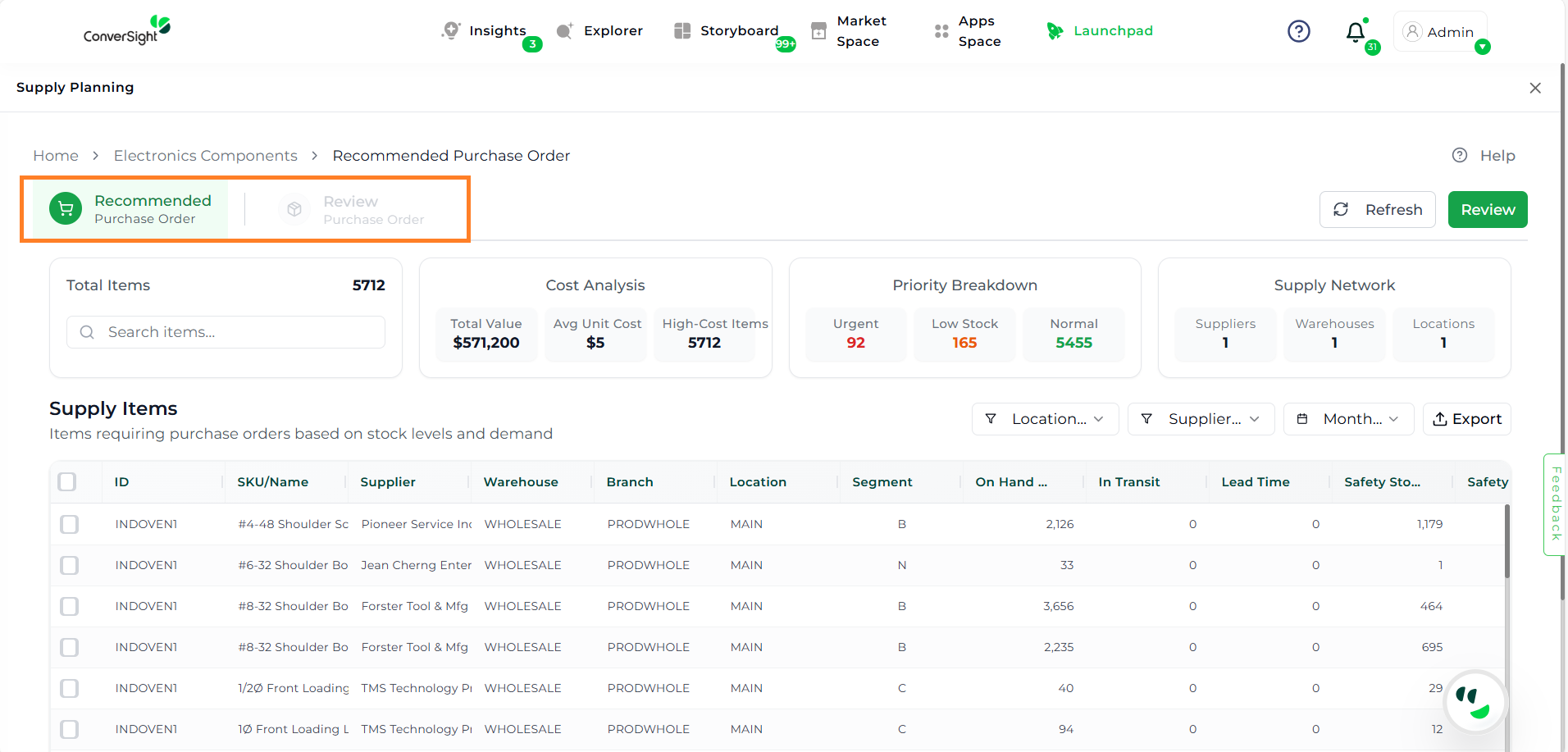

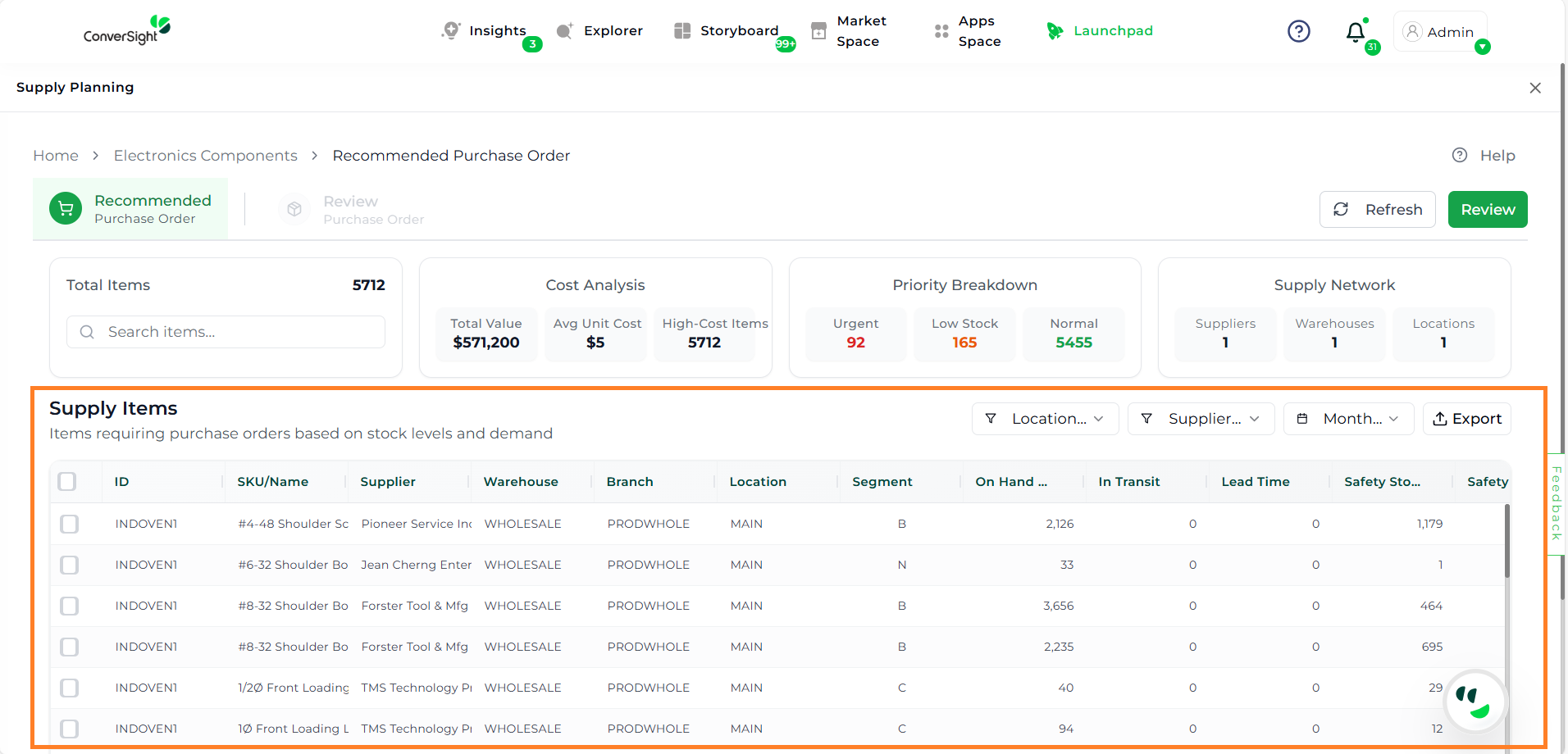

Working with the Recommended Tab#

The Recommended Tab is your primary workspace for analyzing inventory needs. It helps users evaluate items based on demand, cost, and risk of stockouts.

Key Sections#

The Recommended Tab and Review Tab contains several key sections that provide insights into item performance, cost, and priority. These sections help users understand the current stock status, financial implications, and urgency levels for replenishment decisions

Total Items – The total number of items included in the configuration.

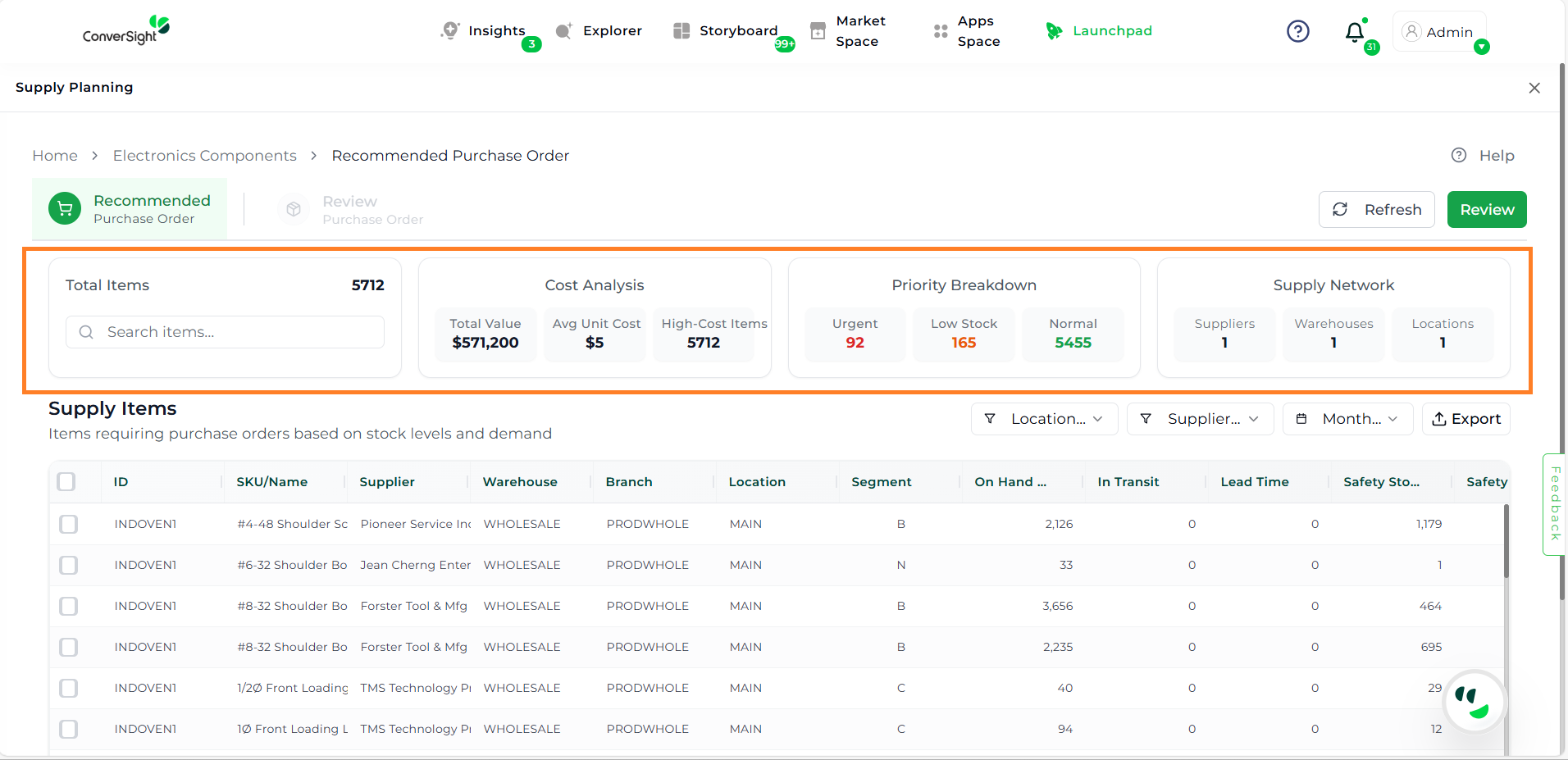

Cost Analysis#

The Cost Analysis section provides an overview of the financial aspects of the configuration, enabling users to assess the overall value and cost impact of their inventory.

Total Value – Shows the combined total value of all items in the configuration.

Average Unit Cost – Indicates cost efficiency by summarizing the average price per unit.

High-Cost Items – Highlights items that contribute significantly to total cost, helping identify areas that may need cost optimization.

Priority Breakdown#

The Priority Breakdown section categorizes items based on their urgency level, allowing planners to quickly identify which products require immediate attention.

Urgent – Items that are close to or already at a stockout level.

Low Stock – Items that are below their recommended buffer or safety stock levels.

Normal – Items that have sufficient stock and do not require immediate replenishment.

Key Sections#

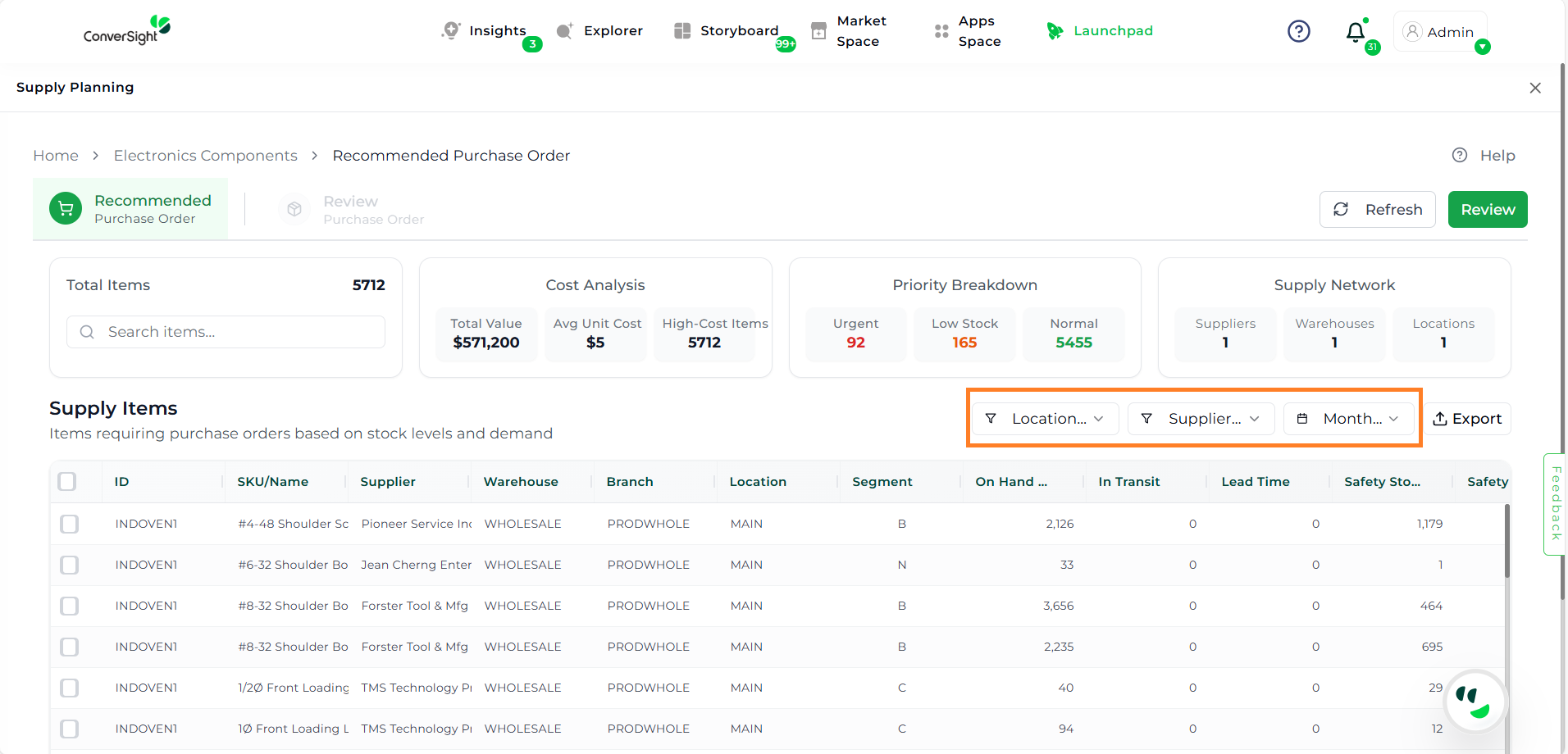

Filters#

Use filters to refine the supply item view:

By Location – Narrow results to specific warehouses or branches.

By Supplier – Focus on items provided by a particular vendor.

By Month – Analyze items by demand or supply in a given month.

Filters#

Supply Items Table#

Gives a detailed breakdown of each item included in the configuration.

Column |

Description |

|---|---|

ID |

Unique system identifier |

SKU / Name |

Stock Keeping Unit and product name |

Supplier |

Vendor providing the item |

Warehouse / Branch / Location |

Storage and distribution details |

Segment |

Category or business segment |

On-Hand |

Available stock |

In-Transit |

Items currently being delivered |

Lead Time |

Number of days suppliers need to deliver after an order |

Safety Stock & Safety Days |

Minimum buffer level expressed in units and equivalent days |

Average Daily Demand |

Typical daily consumption rate |

Primary Action |

AI-suggested status for the item: |

Recommended Quantity |

AI-suggested reorder amount |

Order Quantity |

User-defined quantity to order |

On Hold |

Marks whether an item is blocked for ordering |

Unit Cost |

Price per unit |

Reorder Quantity |

Standard replenishment level |

Promised Date |

Expected supplier delivery date |

Order Type |

Classifies the order (e.g., standard, urgent) |

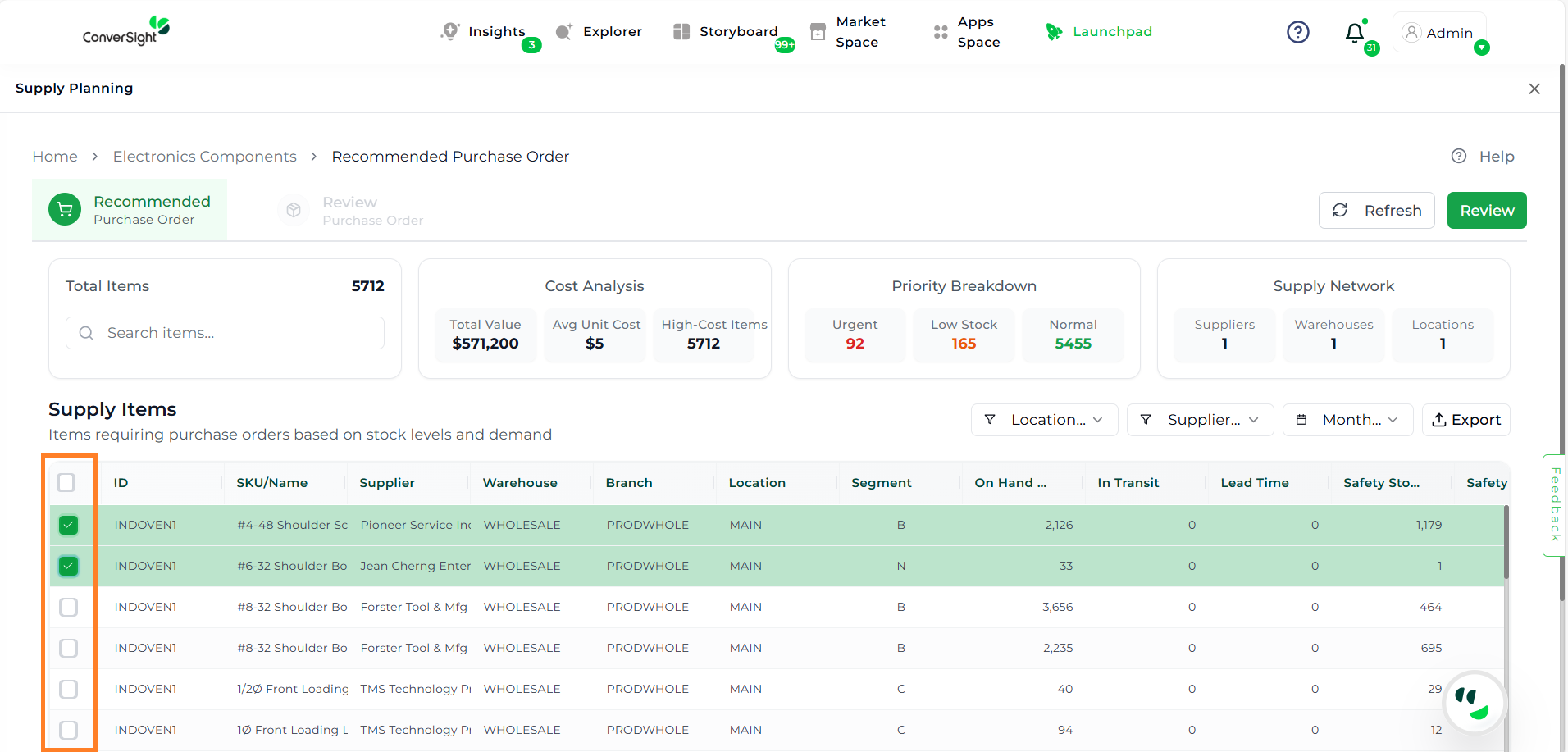

Placing a Purchase Order#

Once users identify items that need replenishment, they can create a Purchase Order (PO). Below are the steps to create your Purchase Order (PO).

Step 1: In the Supply Items Table, select the items you want to include:

Use the checkbox next to each item.

To select all, check the box at the top of the table.

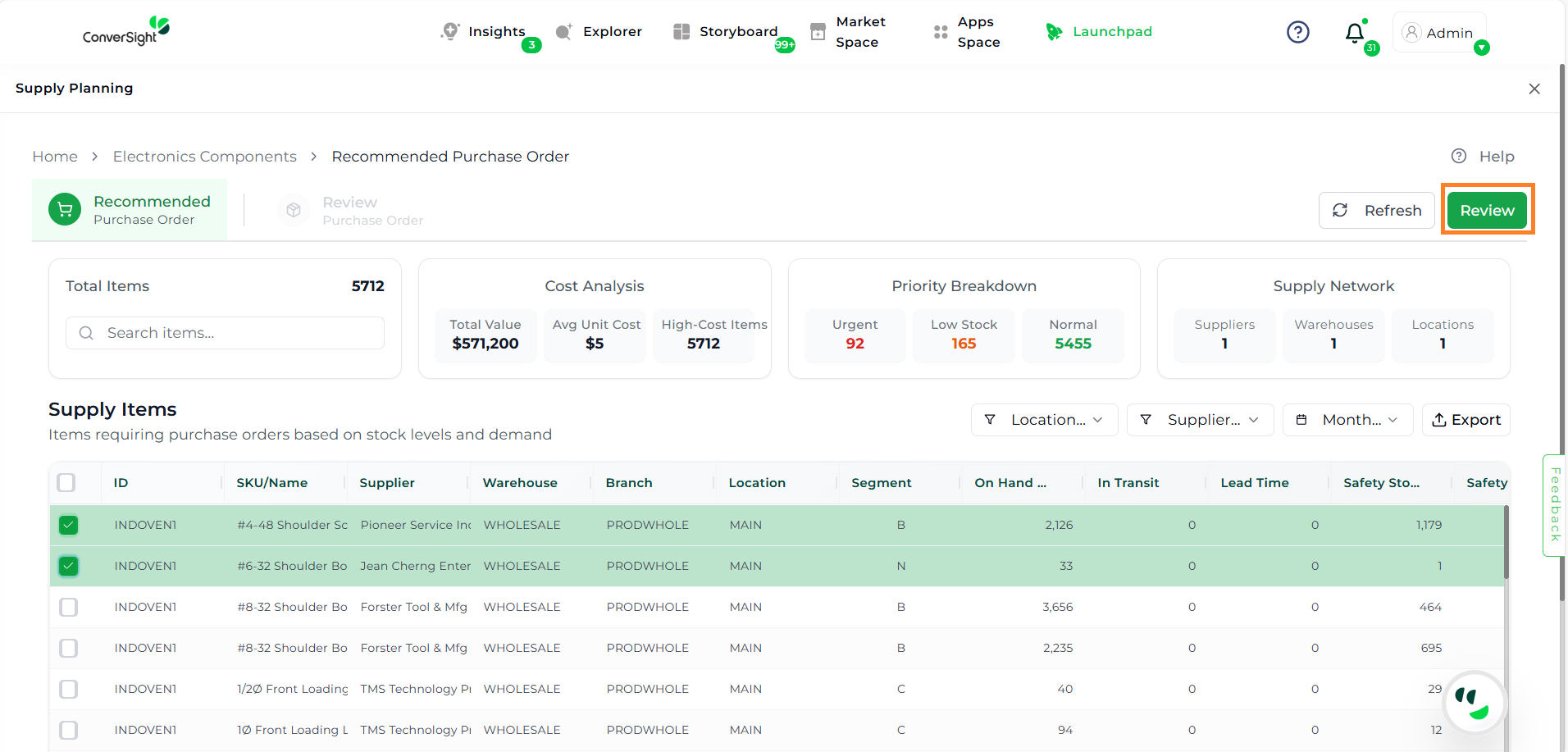

Step 2: Click the Review button.

Step 3: The selected items will appear in the Review Tab.

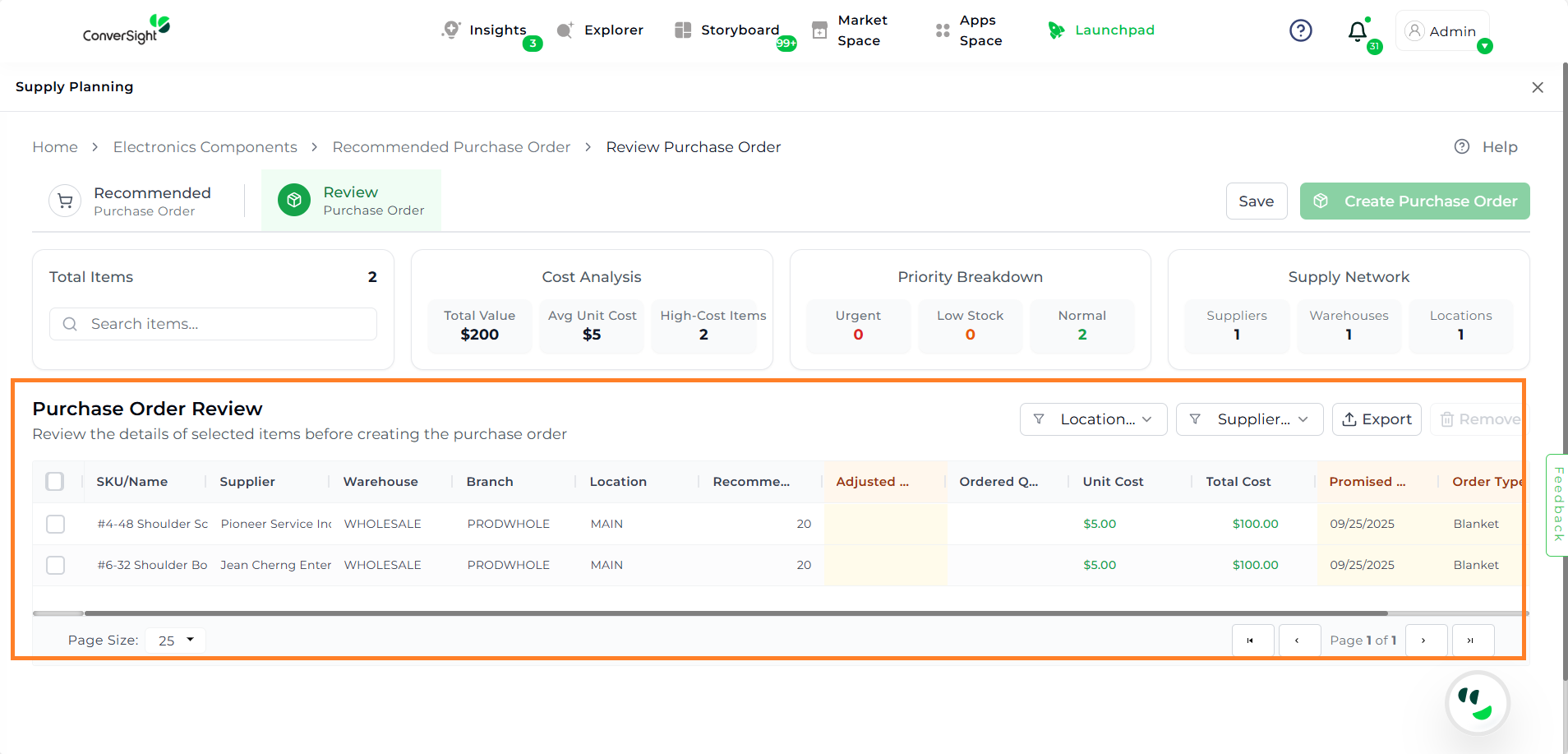

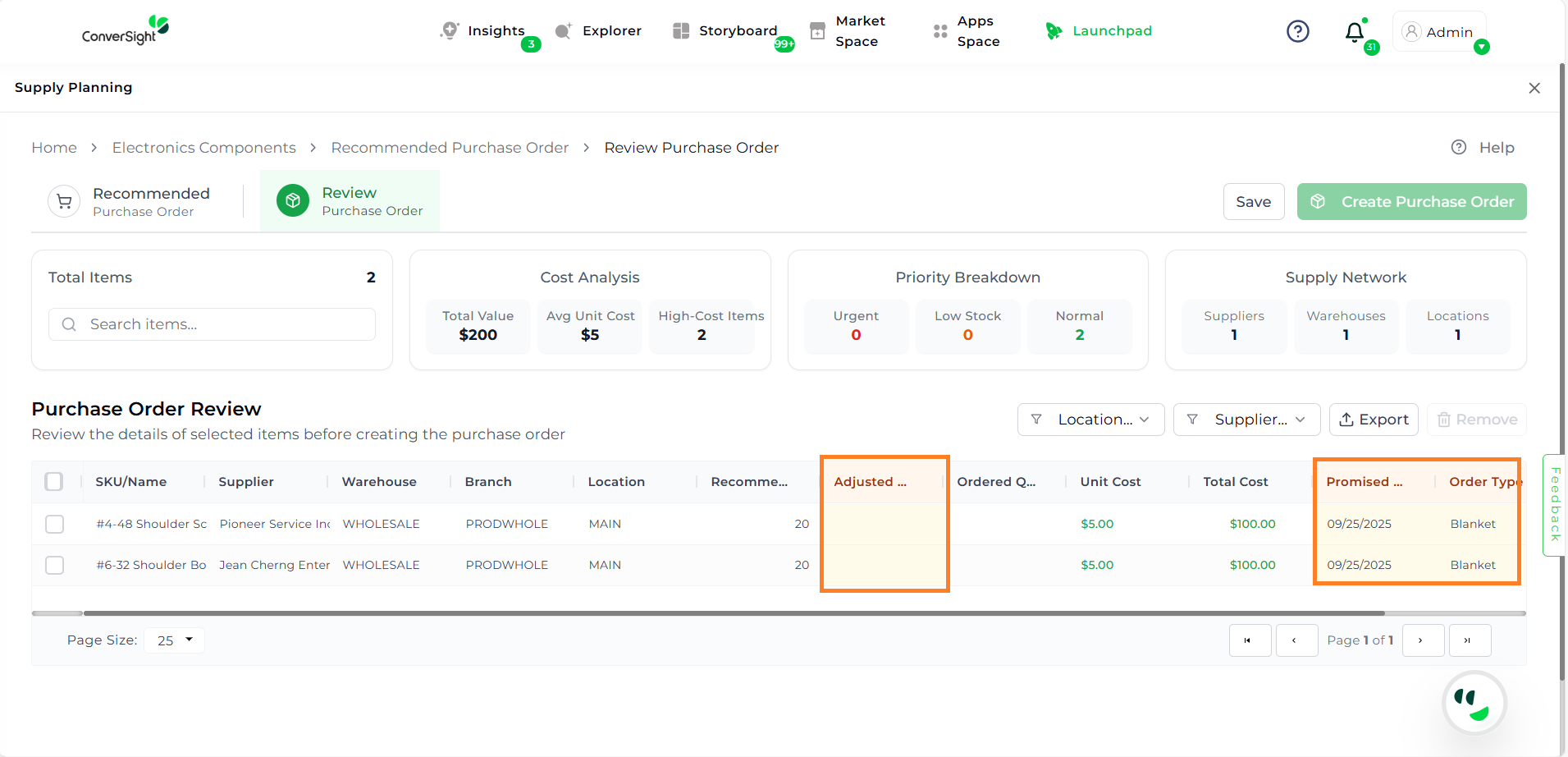

Finalizing Orders in the Review Tab#

The Review Tab displays only the items you’ve selected for ordering. Users have the option to edit the following columns:

Adjust Quantities – Modify the suggested order quantity if needed.

Set Promised Date – Enter the expected delivery date from the supplier.

Choose Order Type – Define whether the order is standard, urgent, or another type.

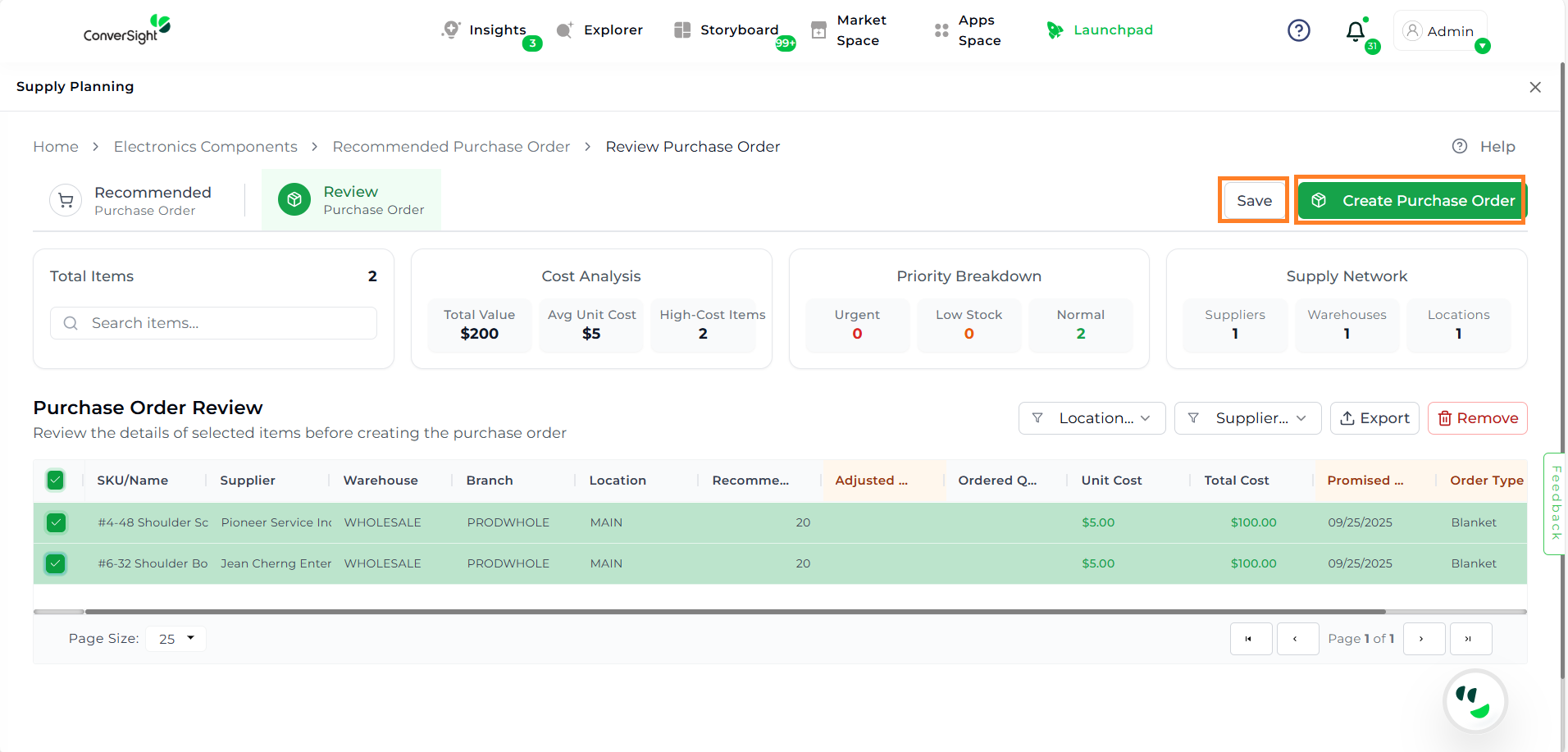

Make any necessary edits to quantities, dates, or order type, then click Save to finalize the PO. To create the PO, select the items by checking their boxes, and finally click Create Purchase Order.

The PO is created and automatically synced with your ERP system. Supply planners can then continue order processing and approval workflows directly in the ERP.

PO Creation Process:

For POs with 20 items or fewer, the app will process the order immediately and display the status on the review screen.

For POs with more than 20 items, the app will initiate a background job for PO creation and provide live status updates on the review screen.

App Notification:

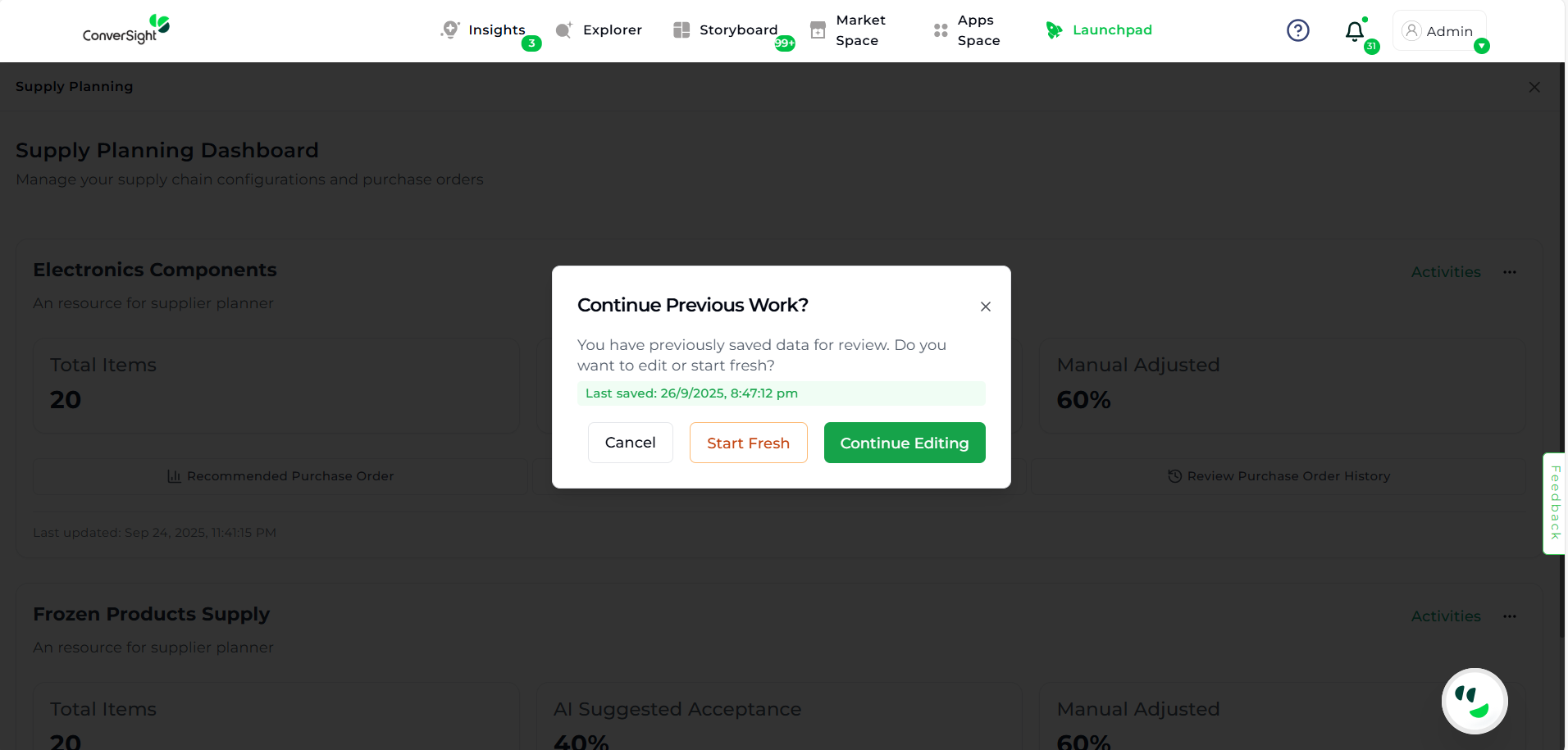

When a user saves data in the Review Purchase Order screen, the same data becomes available to all users within the same organization.

If another user — or even the same user — tries to access the Review Purchase Order, the system will display a notification stating that previous data was saved by a user. The notification will prompt the user to either:

Edit the existing data

Start fresh with a new entry

Any action taken will be reflected for all users within the organization.

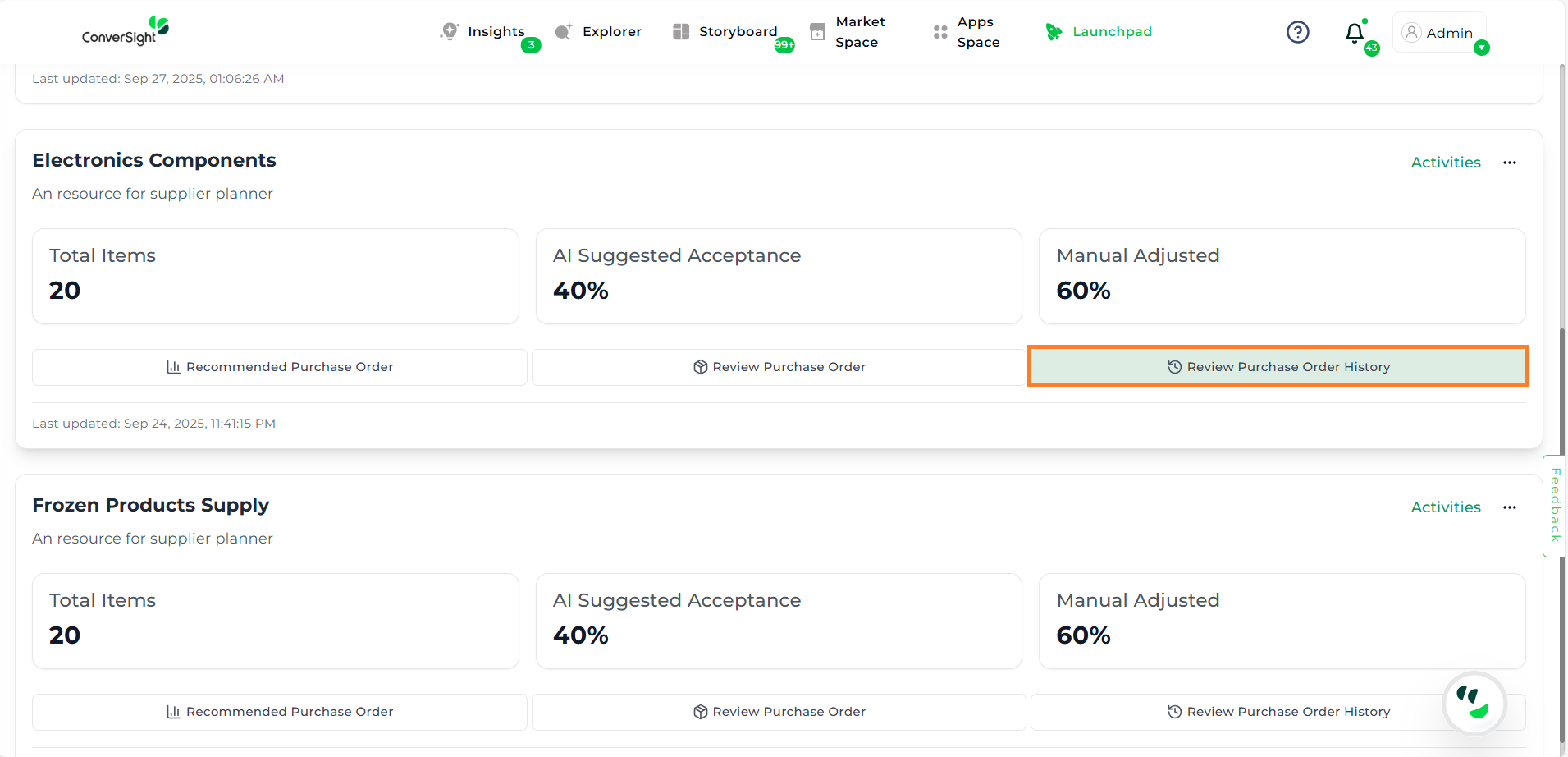

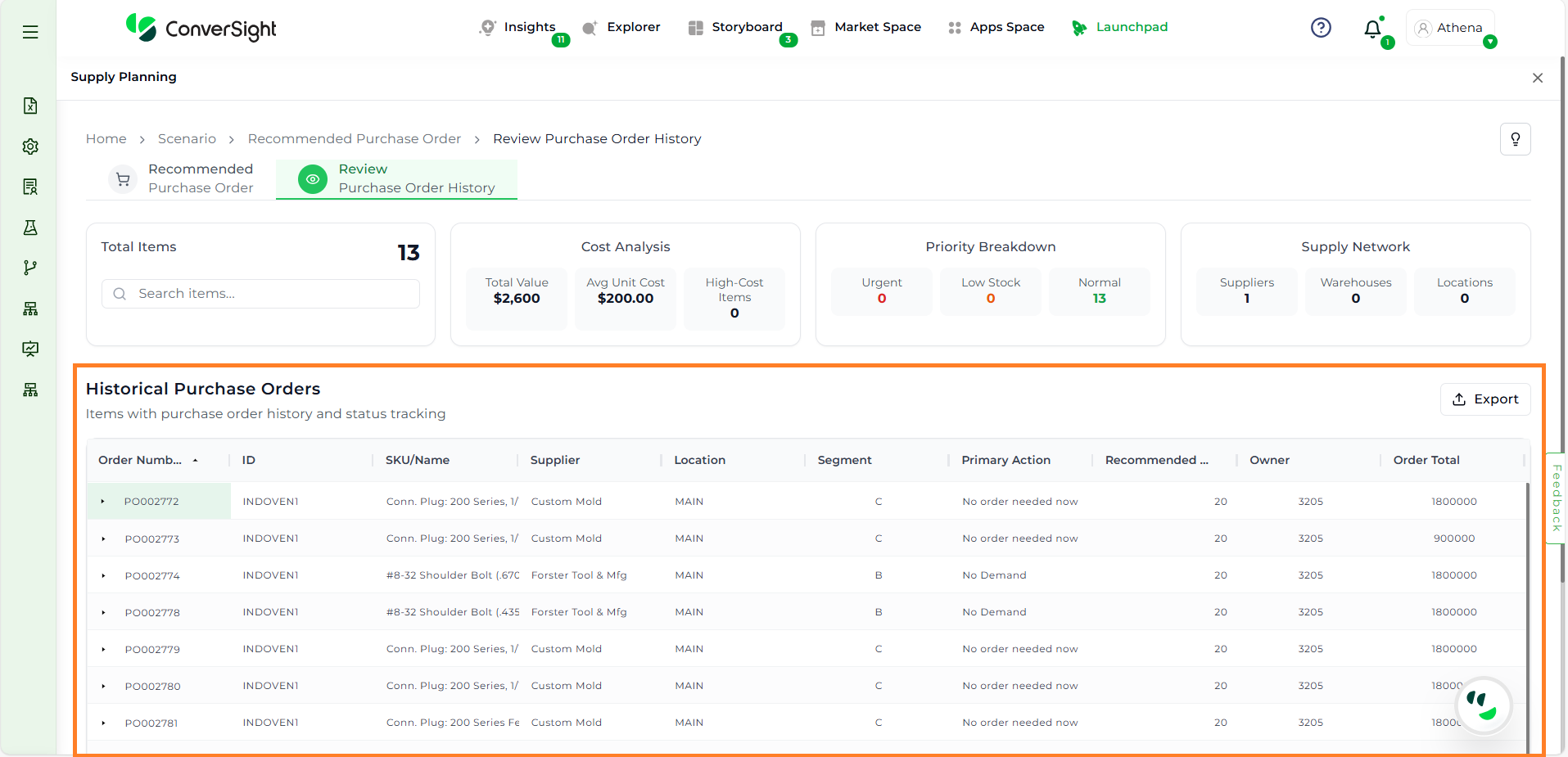

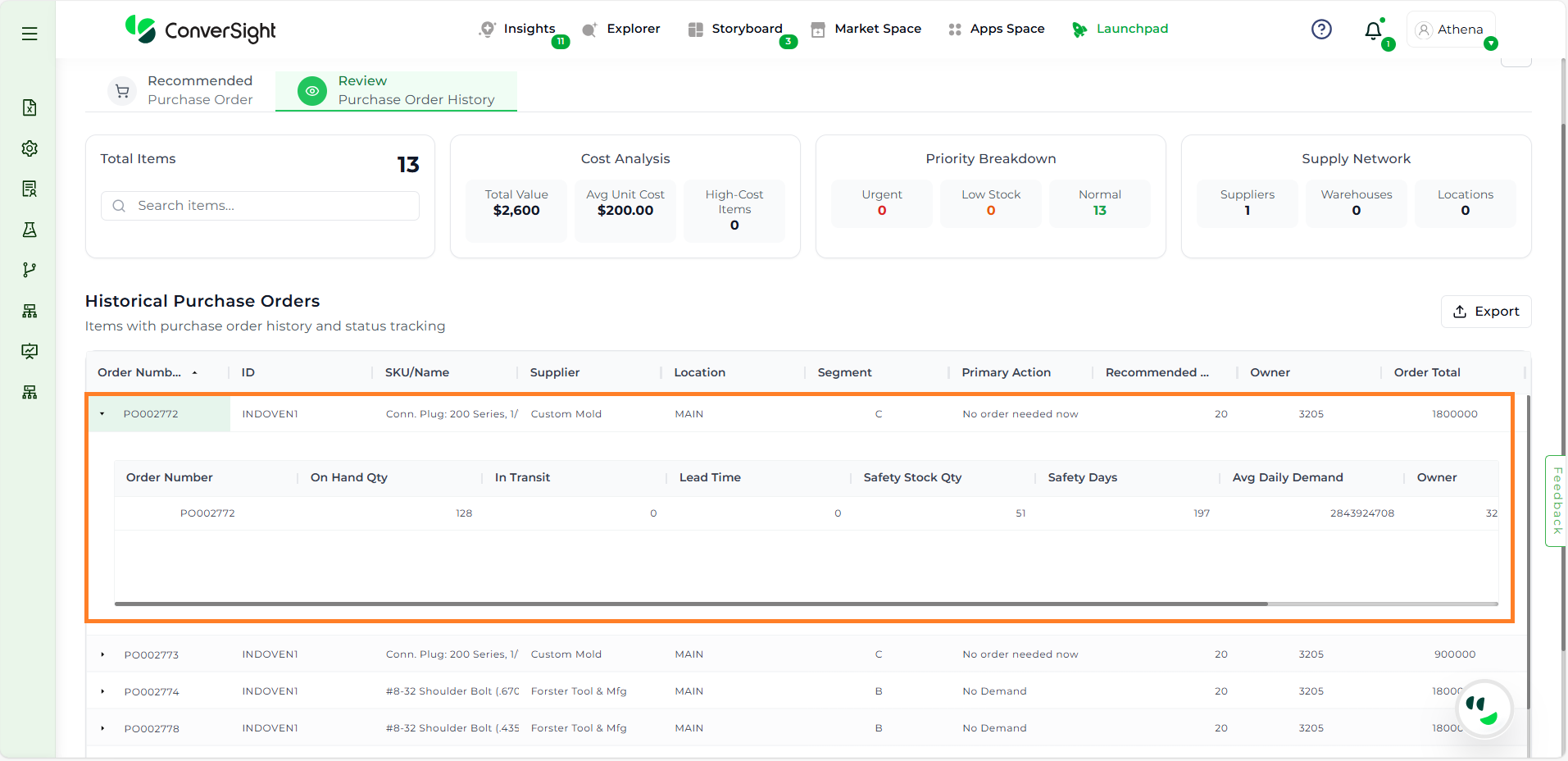

Review Purchase Order History#

The Review Purchase Order History displays a list of purchase orders along with key details such as Order Number, Supplier Code, Supplier, Recommended Order, Owner, and Order Total, allowing users to easily track and review order information.

Review Purchase Order History#

You can view the complete details of each item by clicking on the respective order number, which will display all relevant information related to that specific order.